My Projects

A brief summary

My Projects

A brief summary

Below are some of my biggest projects that I tackled throughout the past couple years that taught me my main technical skillsets. These projects expanded my knowledge on Python, C/C++ and Verilog, while also learning fundamental frameworks like SQL, PyQT, and Tkinter.

The purpose of this project is to simulate the bioelectrical interface between a heart and a real-time microcontroller or in other words, create a cardiac pacemaker. The pacemaker is responsible for monitoring the operation of an individuals heart and providing electrical pulses at certain times to allow the heart to contract and perform its natural function. The pacemaker is required to perform correctly, otherwise the patient could die if there are incorrect electrical pulses. We were required to create the functionality of the pacemaker using MATLAB, and also create the device controller-monitor (DCM) for the pacemaker. A login and signup form was required, with a maximum of 10 users allowed to register. The front-end UI was created using QT designer, that involved CSS for visual aspects, while the back-end portion of the project was done in Python with a future database update coming soon to store all the data on a MySQL server.

With the use of a Texas Instruments MSP432E401Y microcontroller, and the use of a VL53L1X time of flight sensor, the project was completed to develop a 3D reconstruction of a surrounding area. The system was programmed in embedded C, and the data reconstruction was done in Python. By using I2C serial communication between the microcontroller and the ToF sensor, the data was able to be exported onto the PC that the device was connected to. The data reconstruction was done by running a python script with imported libraries such as open3D, to read the exported coordinates, convert them, and construct the image on a geometric plane.

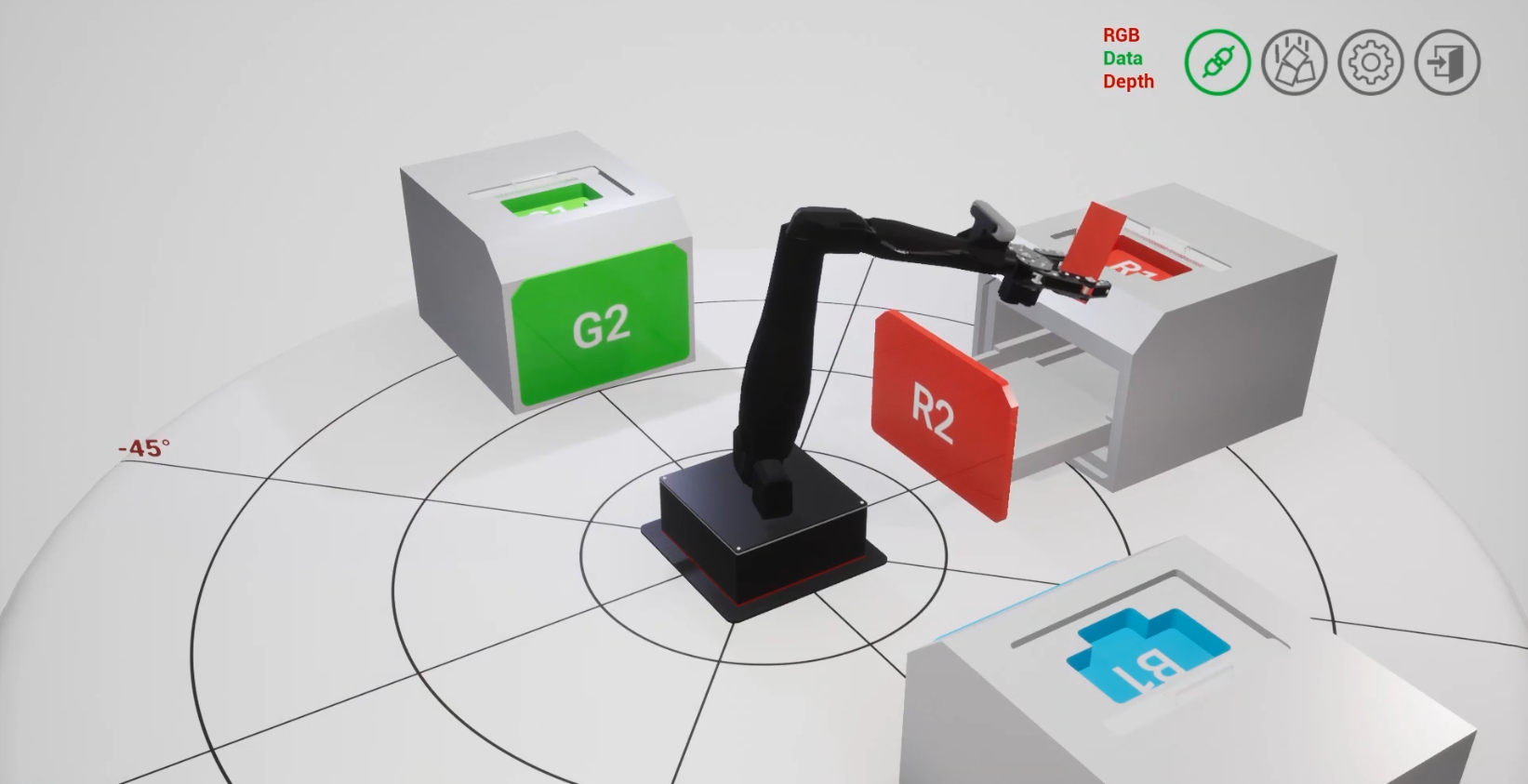

The purpose of this python code was to control a virtual robotic arm to perform tasks in Quanser Interactive Labs, using a separate server. The code was written and run on a Raspberry Pi 3, and our goal was to pick up and drop off a container into specific location coordinates based on the container's color and size. The arm was programmed to move 4 parts which were the base rotation, base angle, elbow, and fingers with several constraints. The code we created also had to incorporate the use of a color sensor so the arm could determine which container it was. Additionally, the arm had to be controlled within the interface with draggable buttons with certain values. These values correspond to each component of the arm.

The purpose of this project was to create a product in Autodesk Inventor that would fit the needs of a client who suffered from lymphoma. We had met with the client a couple of times to discuss design possibilities regarding what she had most difficulty with, and what exactly would be most comfortable for her. With this, we split up as a group to individually create prototypes of our own designs. My thought process included her difficulty of holding a utensil with pressure and comfort, so I put together a rough sketch and created this prototype out of cardboard. The prototype was designed to effortlessly hold a utensil without the need for pressure, and still be accurate and stable.

We then collaborated, narrowed down, and combined prototypes to finalize the product. Out of the 250+ teams in Engineering assigned with this project, I was able to push our team to success as the project lead to place top 10. Being the project lead taught me how to build more effective relationships, especially when there are individuals who are in need of help. This experience was a huge achievement as not only were we evaluated by faculty, the client herself came through to consider our product.